brinell hardness test advantages|brinell hardness tester diagram : traders The most important procedures and their advantages and disadvantages are explained in more detail below: Brinell hardness test (explained in this article) Vickers hardness test. Rockwell hardness test.

web20 de jul. de 1998 · Learn about the Ascension, the Christian belief that Jesus Christ ascended into heaven 40 days after his Resurrection. .

{plog:ftitle_list}

Aprende a tocar el cifrado de Convite de Casamento (Luan Santana) en Cifra Club. A gente morou e cresceu / Na mesma rua / Como se fosse o Sol e a Lua / Dividindo o .

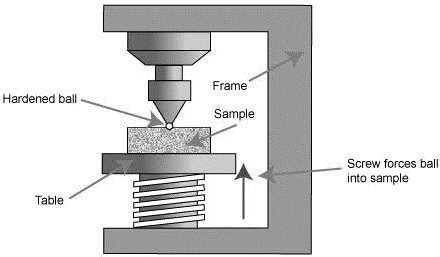

brinell hardness tester diagram

Hall Effect Thickness Gauge (Bottle Thickness Tester) distribution

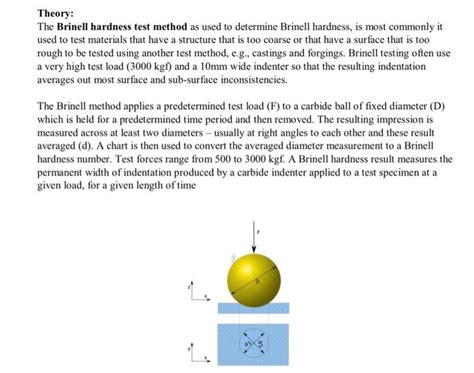

The Brinell Hardness Test method is used to evaluate the hardness of the object, especially for non-ferrous metals, cast irons, and steel products at the higher strength ranges .In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the .The advantages of the Brinell hardness test make it a valuable tool in materials testing, quality control, and research and development. Its ability to provide comprehensive hardness .The Brinell method has the following advantages: The Brinell method can be used for testing non-homogeneous materials (e.g. castings), because the large ball comes into contact with .

The Brinell hardness test offers advantages such as being effective for materials with coarse structures and providing an average hardness over a larger area. However, it has .

The most important procedures and their advantages and disadvantages are explained in more detail below: Brinell hardness test (explained in this article) Vickers hardness test. Rockwell hardness test.The Brinell method offers the following advantages: The Brinell method can be used for testing non-homogeneous materials (e.g. castings), because the large ball comes into contact with many crystals (different metallographic . One of the key advantages of the Brinell test is its ability to provide a comprehensive measure of a material’s hardness, taking into account its resistance to deformation over a relatively large area. This makes it . Hardness Test: Suitable Materials: Advantages: Disadvantages: Applications: Load Range (kgf*) Indentation Type: Standards: Rockwell C (HRC) Metals, Alloys: . Brinell Hardness Test. The Brinell hardness test is ideal for measuring the hardness of metals with coarse or inhomogeneous grain structures, such as cast iron and softer metals like .

Brinell hardness test uses a steel or tungsten indenter of a specified size and a specified load to make an indent on the test sample. IV. Advantages and Disadvantages of Brinell Hardness. Advantages: The Brinell method does not require the test sample to be prepared for inspection. This method can be used to test materials with irregular surfaces.

6. General types of hardness testing... Current practice in USA divides hardness testing into two categories: Macrohardness: Refers to testing with applied loads on the indenter of more than 1 kg and material being tested .The Leeb method is a quick and portable hardness test method, which is determined by the ratio of rebound velocity to the impact velocity of a moving impact body. It is best applied to solid parts of the object for example casting and forgings. In the article, we include the advantages and disadvantages of Leeb method in details.The Brinell hardness test (HBW) serves as a crucial scale for quantifying material hardness, defined in ASTM E10 and BS EN ISO 6506-1 standards. . Some of the advantages of the Rockwell hardness test include: A Simpler planning stage than the Brinell test method which requires decisions, such as the selection of the appropriate force, to be .

brinell hardness test theory

A Brinell hardness testing machine is depicted in Fig.5.19. . The Vickers test has the following advantages over the Brinell test. 1. The diagonals of the square indentation can be measured more accurately than the diameters of the circles. 2. This method is suitable for hard materials as well as for soft materials.Hardness test blocks Hardness Testing Consumables Products. ATM Qness GmbH. Search. English. English; . Product Advantages. DAkkS calibration: according to current ISO and ASTM standards . Brinell Hardness Test Blocks DIN EN ISO 6506-3, ASTM E10. Order Data. Knoop Hardness Test Blocks DIN EN ISO 4545-3, .Knowing the best-suited hardness test of the three, Rockwell, Brinell, and Vickers, for your hardness test will require that you understand the determining criteria for employing any hardness test. . Advantages: Brinell tests are most suitable for rough surfaces and materials as the first widely accepted hardness testing method. It utilizes a .Advantages of Brinell Hardness Test: Suitable for rough or irregular surfaces: The spherical indenter used in the Brinell hardness test can accommodate variations in the surface of the material being tested. This makes it suitable for testing materials with rough or irregular surfaces.

Denoted by NDT(Non-Destructive Testing) It is a technique to inspect and test a sample without any damage so that it can be used for the further process if found OK. The first machine used to test steel bearing races. Rockwell hardness test experiment The Rockwell hardness test is, A technique used to calculate the hardness of a material.

Hardness testing is a crucial aspect of metallurgy, as it provides valuable insights into a material’s mechanical properties and overall quality. There are various methods available for measuring hardness, each with its own set of advantages and limitations. In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method over other .Electronic Brinell hardness tester; Digital Brinell hardness tester (touch screen) Visual Brinell hardness tester (touch screen) Fully automatic Brinell hardness tester; Brinell hardness image processing system; Vickers hardness tester series

The Brinell method has the following advantages: The Brinell method can be used for testing non-homogeneous materials (e.g. castings), because the large ball comes into contact with many crystals (different metallographic constituents of the material), thereby forming a .The large LCD display also informs the operator of what indenter that needs to be used with the selected Brinell scale. Brinell Hardness Tester - QualiBrineller Application. Suitable for Brinell hardness in production, shop floor, and lab environments; Ideal for low to medium testing volumes; Brinell Hardness Tester - QualiBrineller FeaturesHardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.HBMS-3000E Large Digital Display Floor Type Electronic Brinell Hardness Tester. Read more HBRVD-187.5 Motorized Brinell, Rockwell, And Vickers Hardness Tester . Our advantages. . The company’s business is to develop automation production line integration technology for hardness testing equipment, and integrate construction units across .

The Brinell hardness test was invented in 1900 by Johan August Brinell and was the first standardised hardness test to be used in the fields of engineering and metallurgy. The method works by clamping the test piece between an .Hardness test: The hardness test is a type of mechanical test used to check the material properties. It helps to eliminate the chances of failure of a specimen before its use. A hardness test can be categorized as a micro and macro hardness test. The types of macro hardness tests are the Rockwell hardness test, the Brinell hardness test, and .

History Behind the Brinell Test. Let’s take a quick glance at the history behind the Brinell test. In 1900, Dr. J.A. Brinell invented this test. As an honor to him, the test named as a Brinell test. It is the oldest hardness test of all time. This test is used to .II. Advantages of Brinell Hardness Test. Brinell hardness test offers many benefits for different materials and applications, especially in the metallurgy and manufacturing industries. Some of the most important advantages include: An irregular or complex geometrical surface does not affect the accuracy of a Brinell hardness test. It is less . 3. W ORKING P RINCIPLE The Brinell hardness test is based on the principle of indentation. A hardened steel or carbide ball (typically 10 mm in diameter) is pressed into the material's surface (10 to 15) sec by using a specified force. The depth or diameter of the resulting indentation is measured, and the Brinell hardness number (BHN or HB) is calculated.How hardness of a material is determined using Brinell hardness test? Give its advantages and limitations. b) Explain Rockwell hardness test in detail. Give its advantages and limitations. There are 4 steps to solve this one. Solution.

Advantages. Wide range of values and loads; Low surface hardness homogeneity; Competitive price; Specifications. Hardness value: Load, kg: Diameter of ball, mm: . Brinell Hardness Test Block 600HB (600±50HB 10/3000/10) Brinell Copper Hardness Test Block 30-100HB (10/250) Brinell Copper Hardness Test Block 30-100HB (5/62,5) We explore the Difference Between Vickers and Knoop hardness test ,and when each test is best suited for specific applications. 713-827-0700 . . their respective advantages, and when each test is best suited for specific applications. . King Tester Portable Brinell Hardness Tester. King Tester $ 5,800.00. Quick View Read more. Add to Wishlist. The Brinell hardness test, which is widely used in numerous industries, offers several unique advantages and some limitations that are crucial for accurate hardness measurement. To choose the most appropriate testing method for specific materials and applications, it is important to understand these factors. Brinell hardness test determines the hardness of a material by pressing a hardmetal ball into the material and measuring the diameter of the impression left. Its advantages include being able to test large samples and providing high accuracy for .

Question: Hardness Test 1) Compare Rockwell and Brinell hardness testing methods. What are some advantages and disadvantages between these two methods? 2) List and explain several factors, which influence the accuracy of indentation hardness testing.

web1. Selecione qual serviço deseja acessar. 2. Aguarde alguns instantes, você será direcionado para sua área de login. 3. Você vai precisar digitar seu usuário e senha para .

brinell hardness test advantages|brinell hardness tester diagram